simTOL – Efficient Statistical Tolerance Analysis

simTOL

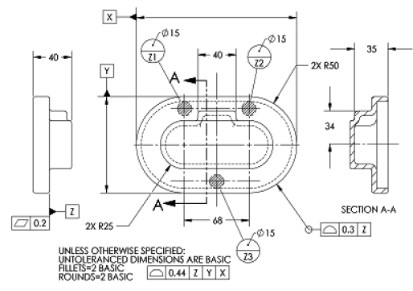

simTOL® from casim offers fast and reliable statistical tolerance analyses for 1D, 2D and 3D tolerance stack calculations enabling you to influence the quality of your products at an early stage in the development process and avoid production cost to skyrocket.

Efficient

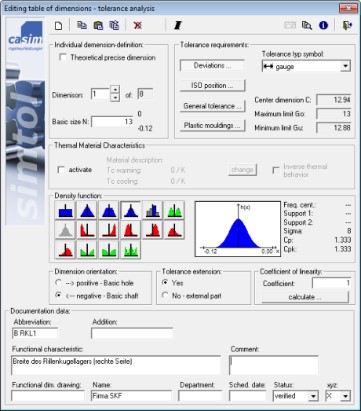

simTOL enables you to quickly work productively on statistical tolerance analysis without a need to be adept in tolerance simulations. Required calculation parameters can be easily selected and allocated. All data is centrally stored in the tolerance data manager enabling reuse for any desired tolerance stacks without further input. A calculation run of a complete assembly can be performed within seconds and clear, concise results are displayed for each critical characteristic with various reports are available for different requirements.

Precise

simTOL operates with statistical algorithms allowing you to calculate precise, real-world results - regardless of how long a tolerance stack is or whether the tolerances of profile and position take effect. simTOL is the result of multiple years of development and has proven itself in years of practical use by our customers in industries like automotive, aerospace, machine design, electronics and many more. Unlike other approaches, simTOL does not use a simple RSS (Root Square Sum)-method for the calculation of the statistical total tolerance. RSS only produces idealized results which includes false positives for all-clear and non-achievable potentials for optimization.

Realistic Results

The manufacturing deviation of components built under real-world processes is an essential factor for the calculation of realistic results. simTOL provides different distribution models for the description of your actual manufacturing processes enabling accurate calculation of realistic tolerances by taking your production methods into account. In addition to that, measured data can be imported and integrated into the calculation.

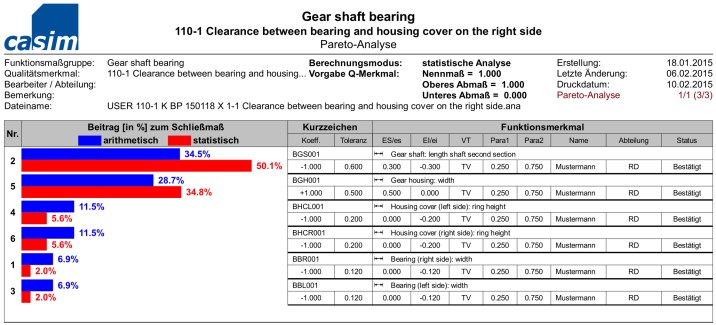

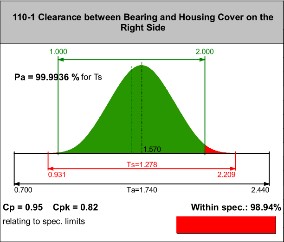

Calculating the accurate statistical total tolerance is just the start. The real objective is to evaluate if the necessary specifications for the assembly can be complied with. simTOL calculates how many assemblies (in %) are within or outside the user-defined specifications. Furthermore, the attainable Cp- and Cpk-values can also be calculated. Last not least, simTOL performs a contributor analysis identifying where the system is particularly sensitive (main contributor) and where optimization measures could best be applied.

Calculating the accurate statistical total tolerance is just the start. The real objective is to evaluate if the necessary specifications for the assembly can be complied with. simTOL calculates how many assemblies (in %) are within or outside the user-defined specifications. Furthermore, the attainable Cp- and Cpk-values can also be calculated. Last not least, simTOL performs a contributor analysis identifying where the system is particularly sensitive (main contributor) and where optimization measures could best be applied.

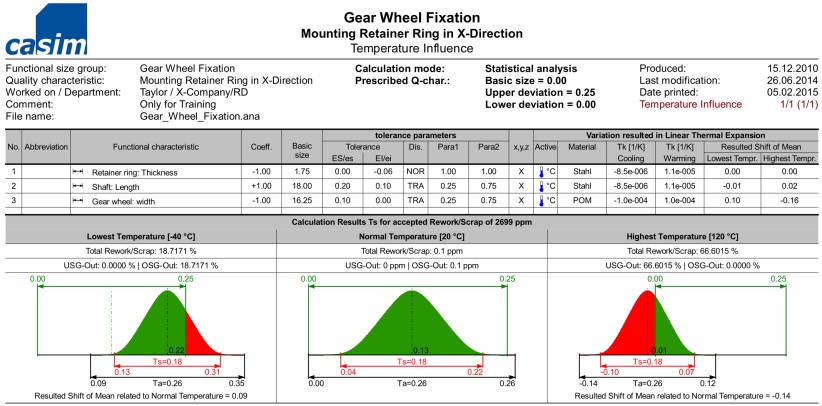

Thermal influences

An optional feature of simTOL allows thermal expansions of components to be considered in the calculation. Within a tolerance stack, thermal expansion coefficients can be selected and defined for any material. Both, the tolerances caused by production and those caused by temperature are calculated in their interaction within the user-defined temperature limits and are displayed in an overall log.

t : +1 706 839 1562 e: info@intrinsim.com